Diesel Engines Powerful but Inefficient

The piston stroke of a diesel engine incorporates as little as 70% of the cylinder volume before the next firing, leaving 30% of the fuel wasted and still burning at the bottom of the power stroke. The partially burned hydrocarbons are left behind as carbon deposits, clogging the engine, contaminating the oil, and producing pollution and smog.

Hydrogen Infusion Improves Diesel Combustion

Hydrogen is the perfect combustion catalyst and is unrivaled in its ability to release more energy than other alternatives. When introduced into the diesel engine cylinder, hydrogen safely promotes a faster fuel burn.

Hydrogen makes the diesel fuel and air mixture burn faster, hotter, and earlier in the power stroke, which pushes the piston down harder (increasing torque) so almost all the fuel burns completely before the exhaust valve is opened near the bottom of the stroke. This increases combustion efficiency and leads to less fuel spent on a given amount of work.

The addition of hydrogen also reduces harmful emissions:

- A more complete burn reduces unburned hydrocarbons, including particulate matter.

- Increased torque produces more pulling power, allowing more work to be done while using less fuel.

- A faster and more efficient combustion process lowers exhaust temperatures for a cooler engine and fewer nitrous oxides (NOx).

Proton Exchange Membrane (PEM) The Enabling Technology

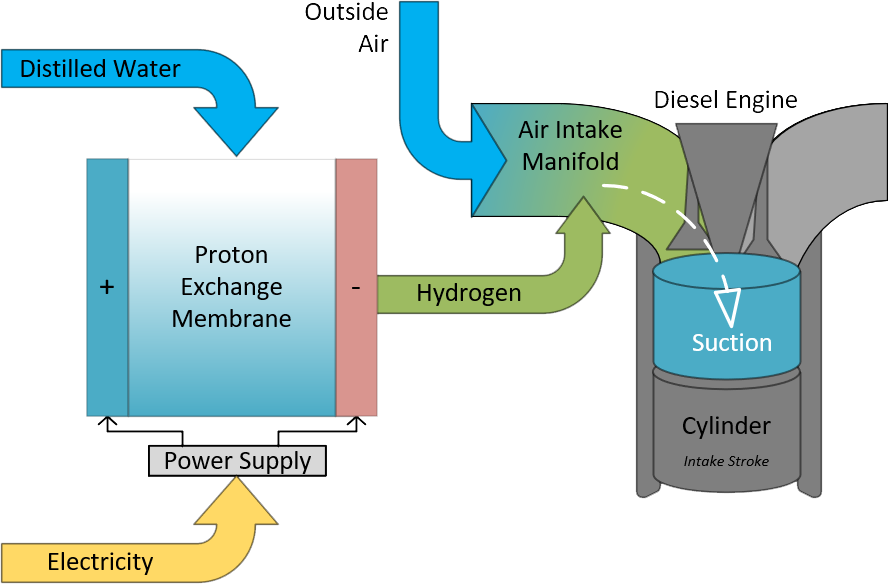

The enabling technology behind D-HAT™ is a patented Proton Exchange Membrane (PEM) cell that safely produces green hydrogen gas on-board and on-demand through an electrolysis process.

The PEM cell produces pure hydrogen gas using only steam distilled water (with no additives) and electricity from an engine’s alternator. It separates the water into hydrogen and oxygen atoms. Only the hydrogen gas is fed through a delivery line and infused through the air-intake manifold, where it becomes part of the ambient airflow, making the combustion process extremely efficient, complete, and clean.

D-HAT™ 6000Case Study: Locomotive

We tested our D-HAT™ technology on a large, 2 stroke locomotive diesel engine in a normal operations study. The D-HAT™ 6000 delivered a 24% reduction in fuel consumption, a massive reduction of harmful exhaust emissions, and less frequent engine maintenance.

D-HAT™ makes a difference you can see:The Safety Of Hydrogen On Demand

The D-HAT™ onboard generator only operates when the engine is running to produce hydrogen on demand from steam distilled water. The PEM electrolysis process completely separates the hydrogen and oxygen, and the pure hydrogen gas is immediately sent into the engine’s air intake system and fully consumed.

On-demand production eliminates the need for onboard hydrogen storage. The minute amount of hydrogen is never under pressure, eliminating any risk of explosion.

The Hydrogen On Demand Process

Each D-HAT™ unit produces up to 4 standard liters of 99.9% pure hydrogen per-minute using one of the most compact and highly efficient electrolysis processes available.

1. Just Add Water

D-HAT’s water-to-hydrogen conversion process starts with steam distilled water (the only thing you ever have to add). The steam distilled water is used as feedstock and pumped to our Proton Exchange Membrane (PEM) fuel cell.

2. Patented Proton Exchange Membrane (PEM) Fuel Cell

Our proprietary PEM cell technology reliably and continuously converts the steam distilled water into hydrogen through an electrolysis process.

3. Scalable Hydrogen Production

Our highly efficient electrolysis process produces more hydrogen using a smaller surface area that most other processes. It draws a fractional amount of power from the diesel engine’s alternator/electrical system to produce up to 4 standard liters of hydrogen per minute, delivering only that hydrogen to the running engine.

4. Up to 99.9% Pure Hydrogen Injection

The hydrogen gas is plumbed into the air-intake manifold using industry-standard tubing and tube fittings. No engine modifications are required.

5. On-time Hydrogen Added in Optimum Amount

The hydrogen-enriched air mixture is introduced into the diesel engine cylinder along with the injected diesel fuel. Since hydrogen burns 10x faster than the diesel fuel, the hydrogen-assisted combustion event is complete. Up to 93% of the fuel is burned very efficiently, producing additional power and torque in each power stroke.

6. More Energetic Fuel Burn = More Torque

The small concentration of hydrogen enriches the air/fuel mixture and assists the combustion of injected diesel fuel to burn more completely. The greater combustion efficiency means the piston is pushed down harder, yielding increased torque, improved fuel economy and reduced emissions.

7. More Carbon Burned Inside Engine = Reduced Harmful Emissions

Our proprietary PEM cell technology reliably and continuously converts the steam distilled water into hydrogen through an electrolysis process.

Maintenance-Free Operations

D-HAT™ systems do not use any electrolytes or additives, making it safe and easy to use, maintain, and refill with commonly available steam distilled water. Just add one gallon of steam distilled water every 1,500 miles, and you are good to go, year-round, in all seasons.

D-HAT™ will help extend the life of your diesel engines by purging them of carbon deposits, so they run better, cleaner, and longer. They will also require significantly less maintenance because of extended service intervals. We also fully back every D-HAT™ system with a limited 300,000 mile (or 7,500 operating hours) 2-year warranty.

In most cases, the D-HAT™ 1000 can be installed and fully functional on any semi-tractor or similar size diesel engine in approximately 4-8 hours.

The Onboard Efficiency Of Hydrogen On Demand

Our highly efficient PEM cell produces up to 4 standard liters of nearly 99.9% pure hydrogen per-minute through electrolysis by drawing minimal amperage from your engine’s alternator. The system consumes approximately one gallon of steam distilled water every 1,500 miles between recommended refills.

System Inputs

About 1 gallon of steam distilled water every 1,500 miles and approximately 65 amps drawn off the engine’s alternator.

System Outputs

4 standard liters per-minute of approximately 99.9% pure hydrogen that increase the combustion efficiency of your engine up to 93%.