Clean Diesel Power

Is No Contradiction. (Neither are the Savings).

We Provide Solutions For:

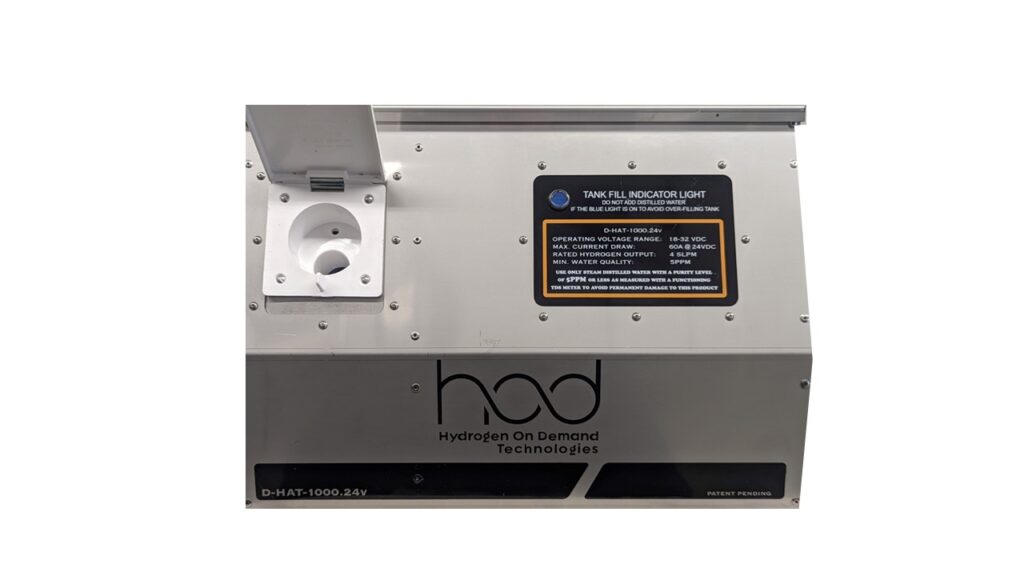

On Road D-Hat

Semi Tractors

Off Road D-Hat

Gen Set, Rail, Mining, Green Hydrogen Power, Filling Stations

Marine D-Hat

Marine Transport

Our Products

| Product |  DHAT 1000 DHAT 1000 |

DHAT 3000 DHAT 3000 |

DHAT 6000 DHAT 6000 |

DHAT 12000+ |

| CONVERSION EFFICIENCY | 92% MINIMUM | 92% MINIMUM | 92% MINIMUM | 92% MINIMUM |

| MAX. HYDROGEN OUTPUT (SLPM) | 4 | 24 | 48 | >48 |

| SYSTEM WEIGHT (APPROX. KG) | 27 | 550 | 710 | 800 OR MORE |

| SYSTEM FOOTPRINT (APPROX. M^2) | <1 | 2-3* | 2-3* | >3 |

| NUMBER OF ENCLOSURES (TYP.) | 1 | 2-3* | 2-3* | >3 |

| ENGINE DISPLACEMENT RANGE (l) | 5-20 | 20-80 | 80-180 | >180 |

| SYSTEM HEIGHT (APPROX.) | 0.5 M | 1.7 M* | 1.7 M* | CUSTOM |

| WATER TANK VOLUME (L) | 8 | 230-460* | 230-460L | CUSTOM |

| INPUT VOLTAGE (V) | 12 - 24VDC | 24 - 148VDC | 12 - 148VDC | 12 - >148VDC |

| INPUT AMPERAGE (A) | 88 MAXIMUM | 216 MAXIMUM | 432 MAXIMUM | >432 MAXIMUM |

| OPERATING TEMPERATURE © | 0-55 | 0-55 | 0-55 | 0-55 |

| STORAGE TEMPERATURE © | -30-65 | -30-65 | -30-65 | -30-65 |

| LCD FOR OPERATORS INCLUDED | YES | YES | YES | YES |

| WIRELESS TELEMATICS INCLUDED | YES | YES | YES | YES |

| VIBRATION DAMPENING INCLUDED | OPTIONAL | YES | YES | YES |

| HEATED EXTERNAL WATER TANK | OPTIONAL | YES | YES | YES |

| COOLING SYSTEM | WATER TO WATER FORCE CIRCULATED |

WATER TO WATER FORCE CIRCULATED |

WATER TO WATER FORCE CIRCULATED |

CUSTOM PER APPLICATION |

| Learn More | Learn More | Learn More | Learn More |

D-HAT 6000™

is a transformative engine efficiency enhancement system for Diesel-Powered Industries. Our D-HAT 6000 state-of-the-art on-board diesel hydrogen-infusion systems promise fuel usage decreases of 10 to 30% and reductions in emissions at a rate of: CO2 20%+, NOx (nitrous oxide) 30%+ and particulate matter as much as 70%. Confirmed in a 2023 in field 100-day normal operations study.

Along with prolonged engine life, the D-HAT 6000™ system significantly reduces the frequency of engine maintenance, such as diesel particulate filter (if required) maintenance and replacement. D-HAT™ 6000 systems are warrantied for two years or 9000 operating hours.

HoD Tec D-HAT 6000™ units deliver an off-the-shelf, fleet-wide solution for dramatic reductions in fuel consumption and engine emissions, with the lowest cost of transition of any alternative optimization ROI.

Truly, D-HAT 6000™ systems afford a no-risk, significant increase in operational efficiency. With D-HAT, fuel and maintenance savings per diesel engine are often in excess of 20% per year, based on average operating hours. The ROI is typically only 12 to 18 months, while lease to buy options usually deliver immediate positive impact to the customer’s bottom line.

Great for the planet, even better for your profitability.

2023 Locomotive Client Trial -Delivers Proven Results

Hydrogen On Demand Technologies (HOD) was engaged to design a solution for large locomotive diesel engines. The first field tested engine was the 2 stroke EMD 645/GP38.

After 3 months of continuous operation, the installed D-HAT™ 6000 delivered an average of 24% fuel consumption reduction. The pilot also delivered massive reduction in green house gas and particulate matter emissions.

Reductions in harmful exhaust emissions including CO2-25+% NOx 35+%, diesel particulate matter (soot) reductions estimated at 70+%. DHAT assisted engines run greener, cleaner while delivering maximum efficiency. Carbon footprints are reduced.

Why Hydrogen On Demand?

Hydrogen on Demand Technologies is the worldwide original equipment manufacturer (OEM) of Diesel Hydrogen Assist Technology (D-HAT™) generators, a certified and warrantied aftermarket device designed to work on all large diesel internal combustion engines (6 liters and larger in size) including trucks, buses, heavy equipment, marine vessels, power generation and more.

D-HAT provides a hydrogen-assisted fuel burn that enhances the combustion characteristics of diesel equipment by increasing overall efficiency to 95% or higher. The results are transformational: by an increasing torque, less fuel is spent for a given amount of work, providing better mileage, higher-performing engines, as well as far fewer pollutants.

The Hydrogen On Demand Process

Each D-HAT unit produces up to 4 standard liters of 99.9% pure hydrogen per-minute using one of the most compact and highly efficient electrolysis processes available.

01 Just add water

D-HAT’s water-to-hydrogen conversion process starts with distilled water (the only thing you ever have to add). The distilled water is used as feedstock and pumped to our Proton Exchange Membrane (PEM) fuel cell.

02 Patented Proton Exchange Membrane fuel cell

Our proprietary PEM cell technology reliably and continuously converts the distilled water into hydrogen through an electrolysis process.

03 Scalable hydrogen production

Our highly efficient electrolysis process produces more hydrogen using a smaller surface area that most other processes. It draws a fractional amount of power from the diesel engine's alternator/electrical system to produce up to 4 standard liters of hydrogen per minute, delivering only that hydrogen to the running engine.

04 Up to 99.9% pure hydrogen injection

The hydrogen gas is plumbed into the air-intake manifold using industry-standard tubing and tube fittings. No engine modifications are required.

05 On-time hydrogen added in optimum amount

The hydrogen-enriched air mixture is introduced into the diesel engine cylinder along with the injected diesel fuel. Since hydrogen burns 10x faster than the diesel fuel, the hydrogen-assisted combustion event is complete. Greater than 95% of the fuel is burned very efficiently, producing additional power and torque in each power stroke.

06 More energetic fuel burn = more torque

The small concentration of hydrogen enriches the air/fuel mixture and assists the combustion of injected diesel fuel to burn more completely. The greater combustion efficiency means the piston is pushed down harder, yielding increased torque, improved fuel economy and reduced emissions.

07 More carbon burned inside engine = reduced harmful emissions

Almost all the fuel burns completely inside the engine before the exhaust valve is opened near the bottom of the stroke. Torque and fuel economy increase while emissions and vehicle maintenance decrease.

Put The Power Of Hydrogen On Demand To Work For You

The addition of D-HAT generators to your diesel-powered equipment can deliver a triple bottom line impact by improving your sustainability position, increasing net operating profitability, while reducing net operating expenses.

SYSTEM WARRANTY

Because we make no modifications to the engine, engine sensors or air-fuel settings, D-HAT hydrogen on demand generators maintain all your original engine warranties.

Hydrogen On Demand Technologies stands behind the performance of our product by offering the following with every purchase:

Limited 3-Year Warranty: 3-year or 300,000 miles (or 25,000 operating hours) warranty that includes parts and labor.

Benchmark Test Report

U.S. Department of Energy Benchmark Test Report

ROI Calculator

Calculate how much fuel and maintenance savings you can take to your bottom line

Solution Overview

Diesel Hydrogen Assist Technology (D-HAT) Solution Overview